In various industries, torque wrenches ensure proper and accurate torque application to fasteners. These torque wrenches come in different types, including manual, electric, hydraulic, and pneumatic. The pneumatic, hydraulic torque wrench pump has gained popularity due to its efficiency, power, and versatility. This article explores the working principles, advancements, and applications of pneumatic hydraulic torque wrench pumps.

Accurate Torque Application

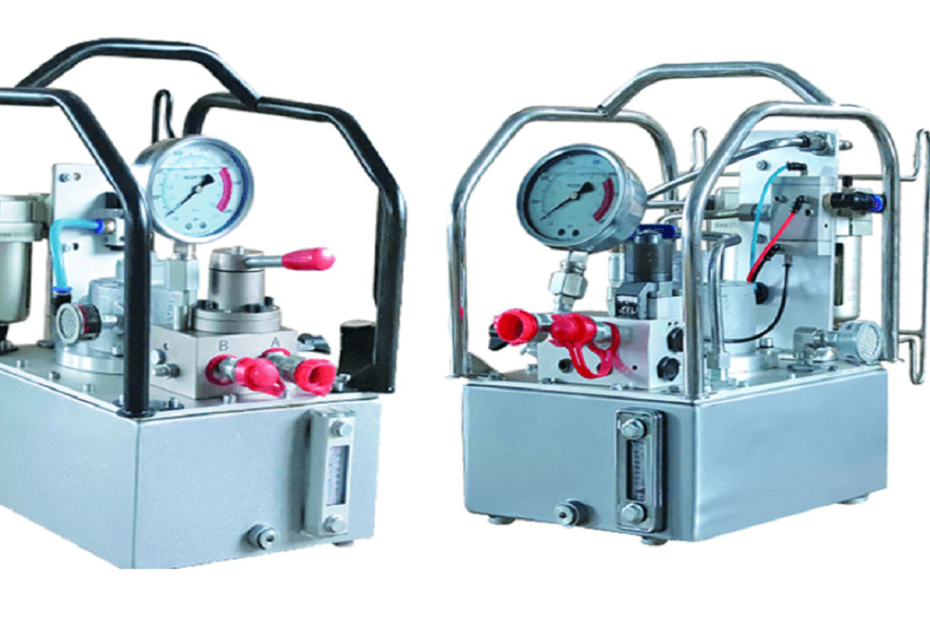

The pneumatic hydraulic torque wrench pump is a specialized tool that operates on a combination of pneumatic and hydraulic principles. It typically consists of an air-driven hydraulic pump, a reservoir, a pressure relief valve, and a high-pressure hose connected to the torque wrench. Compressed air powers the pump, which increases pressure inside the pool. This pressurized hydraulic fluid is directed through the hose and into the torque wrench, creating the required torque force.

The pump’s design allows for precise hydraulic pressure control, translating to accurate and consistent torque application to fasteners. The pneumatic aspect of the tool provides high power-to-weight ratios, making it suitable for various heavy-duty applications.

Remote Control and Connectivity

As technology advances, some pneumatic hydraulic torque wrench pumps now come equipped with remote control capabilities. This feature allows operators to adjust torque settings and monitor torque values from a safe distance, minimizing the need for physical proximity to the equipment being torqued. Additionally, connectivity features enable data logging and real-time torque monitoring, facilitating maintenance tracking and quality control in various industrial settings.

Specialized Accessories and Attachments

Manufacturers have developed specialized accessories and attachments to enhance the versatility and adaptability of pneumatic hydraulic torque wrench pumps. These include reaction arms, extension adapters, and cassettes that enable the pump to accommodate a wide range of fastener sizes and configurations. Such accessories ensure that the pump can easily tackle complex torque tasks in various industries.

Intelligent and Automated Torque Solutions

Integrating artificial intelligence and intelligent technologies paves the way for automated torque solutions. Some pneumatic hydraulic torque wrench pumps now have innovative torquing systems that can self-adjust based on specific parameters and feedback. These mechanical systems can optimize torque application, detect anomalies, and provide insights for preventive maintenance, contributing to improved efficiency and reduced downtime in industrial operations.

Energy Efficiency and Sustainability

With growing environmental awareness and the need for sustainable practices, pneumatic hydraulic torque wrench pumps, using compressed air as the power source have undergone significant developments to improve energy efficiency and reduce their environmental impact. Manufacturers have focused on optimizing pump design, reducing air consumption, and incorporating energy-saving features to minimize overall energy requirements. Using energy-efficient components and technologies, these pumps contribute to lower carbon emissions and a reduced ecological footprint, making them more appealing to environmentally conscious industries and projects.

Critical Machinery Support

The pneumatic hydraulic torque wrench pump has become an indispensable tool in various industries, where accurate torque application is essential for safety, efficiency, and reliability. With continuous advancements in design and technology, these pumps have become more efficient, safer, and easier to use. Their applications span across industries, ensuring the integrity and performance of critical machinery and structures. Pneumatic hydraulic torque wrench pumps will continue to be essential tools for improving workplace efficiency and safety as the industry changes.